Ultra 20 Point Inspection

Regular *inspections are an important part of maintaining your heating and cooling system. HVAC systems in Tucson normally run for over 4,000 hours each year! That would be like your car running at 45 mph for 180,000 miles. Ultra wants to help you and your family “Live Comfortably” so we recommend that you inspect up your HVAC system twice a year, once before winter and once before summer, to be prepared for the temperature extremes in the desert.

For a Limited Time, Ultra is offering a $49 seasonal inspection for your system.

Residential customers only. This offer is good Monday-Friday, 8AM-4PM excluding weekends, evenings and holidays. Realtor inspections are available for $199. Some restrictions apply.

*See below for a full list of what is included in the 20 Point inspection.

Unit not Working?

Or fill out the form below.

Our NATE-certified technicians are standing by.

"* Required" indicates required fields

$69 Service Call

For AC Repair in Tucson, Call Ultra Air Conditioning today at (520) 729-9713. We are Tucson's #1 choice for professional home and office air conditioning repair. You'll have peace of mind knowing your comfort is assured. At Ultra Air, we really do care!

Special $49 for Seasonsl System Inspection

For a limited time, we are offering a seasonal system inspection for only $49. Call ULTRA and have one of our certified technicians help you keep your system working in tip-top shape. Call Ultra Air today.

TEP Participating Partner

As a TEP Participating Partner, our goal is to provide you with the best customer service available and to save you money, including a seasonal system inspection for only $49! Call Ultra Air Conditioning for all of your HVAC needs!

For a Limited Time, Ultra is offering a $49 seasonal inspection

This type of regular maintenance has many benefits including:

- It keeps your manufacturers’ warranty valid.

Your manufacturer may not honor a warranty if your unit has not been properly maintained. We recommend regular maintenance and that you keep a record of the services performed in case you need it for a warranty claim. Better yet, join the Ultra Performance Club and let our Nate Certified Technicians maintain your system and keep records for you. - Save money on your heating and cooling bills.

According to the U.S. Department of Energy, a homeowner can save up to 10% annually on their energy bills when properly maintaining their HVAC systems. Regularly maintained systems last longer, saving you money in the long run. - Assures a more reliable heating and cooling system.

Regular inspections will minimize the cost of repairs by catching problems and fixing your system before serious, more costly repairs. - Safety.

Whether gas, electric or both HVAC systems must be properly inspected and maintained to prevent a number of dangerous situations. We check for safety issues such as gas leaks, carbon monoxide leaks and electric shorts which can be prevented through regular maintenance. Ultra’s inspections can help identify these issues before they become a serious and more costly problem.

The $49 inspections won't last long!

What does the 20 Point inspection include?

Thermostat – We check all thermostat connections for looseness that could cause short cycling or inaccurate readings. When possible, we verify calibration to make sure temperature settings are precise and your system is running as intended.

Split Temperatures – Your technician measures the temperature difference between the air entering and leaving the evaporator coil. A normal temperature split of about 17–20°F helps confirm that your system is cooling effectively.

Split Temperatures – Your technician measures the temperature difference between the air entering and leaving the evaporator coil. A normal temperature split of about 17–20°F helps confirm that your system is cooling effectively.

Air Filter – We inspect your air filter for dirt, debris, or buildup that can restrict airflow. A dirty filter not only reduces efficiency but can also put extra strain on your system. We’ll recommend replacement if needed.

Air Filter – We inspect your air filter for dirt, debris, or buildup that can restrict airflow. A dirty filter not only reduces efficiency but can also put extra strain on your system. We’ll recommend replacement if needed.

Blower Wheel – The blower wheel is examined for balance and buildup that could impact performance. A clean, properly balanced blower wheel helps ensure smooth operation and even airflow throughout your home.

Blower Wheel – The blower wheel is examined for balance and buildup that could impact performance. A clean, properly balanced blower wheel helps ensure smooth operation and even airflow throughout your home.

Air Ducts – We inspect visible ductwork for signs of dirt, damage, or leaks. Air leaks or collapsed ducts can cause temperature inconsistencies and energy waste, so catching them early can prevent larger issues.

Air Ducts – We inspect visible ductwork for signs of dirt, damage, or leaks. Air leaks or collapsed ducts can cause temperature inconsistencies and energy waste, so catching them early can prevent larger issues.

Disconnect Box – We verify that all electrical connections in the disconnect box are secure and inspect for corrosion or discoloration that might indicate overheating or metal fatigue.

Disconnect Box – We verify that all electrical connections in the disconnect box are secure and inspect for corrosion or discoloration that might indicate overheating or metal fatigue.

Fuses – Your technician checks the condition of all fuses for swelling or damage. If there are signs of water intrusion or loose wiring inside the disconnect box, we’ll make recommendations for repair.

Fuses – Your technician checks the condition of all fuses for swelling or damage. If there are signs of water intrusion or loose wiring inside the disconnect box, we’ll make recommendations for repair.

Contractors – We inspect the contactor switch for wear, pitting, or discoloration. Burnt or worn contact points can lead to inconsistent startup or system failure if left unchecked.

Contractors – We inspect the contactor switch for wear, pitting, or discoloration. Burnt or worn contact points can lead to inconsistent startup or system failure if left unchecked.

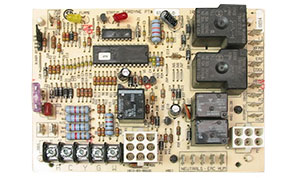

Start Kit | Relays | Transformers – We examine these critical electrical components for loose connections, vibration wear, or burnt wiring. Each part is checked to ensure it’s securely mounted and operating properly.

Start Kit | Relays | Transformers – We examine these critical electrical components for loose connections, vibration wear, or burnt wiring. Each part is checked to ensure it’s securely mounted and operating properly.

Run Capacitors – Capacitors are tested with a multimeter to confirm they are within 10% of their rated microfarads. We also check for oil leaks, bulging, or signs of voltage loss that could indicate failure.

Run Capacitors – Capacitors are tested with a multimeter to confirm they are within 10% of their rated microfarads. We also check for oil leaks, bulging, or signs of voltage loss that could indicate failure.

Compressor – Check to start amp draw along with running amps. Compare to unit ratings. Look for burnt wires at compressor terminal.

Compressor – Check to start amp draw along with running amps. Compare to unit ratings. Look for burnt wires at compressor terminal.

Refrigerant Levels – Proper refrigerant charge is key to efficient operation. We test system pressures and will only add refrigerant after repairing any detected leaks to prevent recurring issues.

Refrigerant Levels – Proper refrigerant charge is key to efficient operation. We test system pressures and will only add refrigerant after repairing any detected leaks to prevent recurring issues.

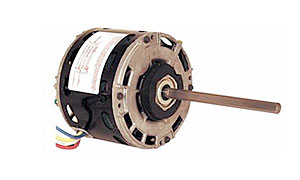

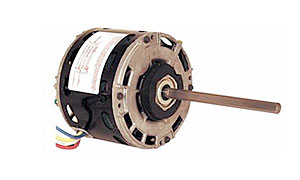

Condenser Motor – We measure motor amperage, check bearings, and ensure fan blades are balanced and free of damage. Lubrication is applied where needed for smooth operation.

Condenser Motor – We measure motor amperage, check bearings, and ensure fan blades are balanced and free of damage. Lubrication is applied where needed for smooth operation.

Condenser Coil – The outdoor coil is checked for temperature difference (typically around 30°F) and cleaned of dirt, dust, or debris buildup that can reduce efficiency.

Condenser Coil – The outdoor coil is checked for temperature difference (typically around 30°F) and cleaned of dirt, dust, or debris buildup that can reduce efficiency.

Blower Motor – We measure amperage draw and compare it to the motor’s rated specifications. The motor is oiled as needed and checked for proper speed and airflow delivery.

Blower Motor – We measure amperage draw and compare it to the motor’s rated specifications. The motor is oiled as needed and checked for proper speed and airflow delivery.

Evaporative Coil – Both sides of the coil are inspected for dust or mold buildup that can block airflow and degrade indoor air quality. A clean coil helps prevent early system failure.

Evaporative Coil – Both sides of the coil are inspected for dust or mold buildup that can block airflow and degrade indoor air quality. A clean coil helps prevent early system failure.

Condensation Drain – We flush and check the drain line for obstructions or bacterial growth that could lead to water leaks or system shutdowns. Rust stains or corrosion are noted for follow-up.

Condensation Drain – We flush and check the drain line for obstructions or bacterial growth that could lead to water leaks or system shutdowns. Rust stains or corrosion are noted for follow-up.

Plenum –The plenum connection is checked for air leaks or poor sealing. Since most air loss occurs here, ensuring a tight seal improves efficiency and indoor comfort.

Plenum –The plenum connection is checked for air leaks or poor sealing. Since most air loss occurs here, ensuring a tight seal improves efficiency and indoor comfort.

Insulation –We inspect insulation around the blower and suction line tubing. Damaged or missing insulation allows heat transfer that reduces overall efficiency.

Insulation –We inspect insulation around the blower and suction line tubing. Damaged or missing insulation allows heat transfer that reduces overall efficiency.

Safety Controls – Finally, we test all safety and high-pressure controls to make sure they’re functioning properly to protect your system from damage.

Safety Controls – Finally, we test all safety and high-pressure controls to make sure they’re functioning properly to protect your system from damage.

HEATING CHECK UP:

Thermostat – We verify thermostat connections and calibration for accurate heating performance and consistent comfort throughout your home.

Air Filter – Air filters are inspected again during the heating check-up to ensure no airflow restrictions or debris buildup that could strain your system.

Air Filter – Air filters are inspected again during the heating check-up to ensure no airflow restrictions or debris buildup that could strain your system.

Blower Motor – The motor’s amperage and performance are tested against rated values. We lubricate moving parts and confirm that the fan speed matches the unit’s settings.

Blower Motor – The motor’s amperage and performance are tested against rated values. We lubricate moving parts and confirm that the fan speed matches the unit’s settings.

Runs Capacitor – We test capacitor values for accuracy within 10% of rating, inspecting for oil leaks or voltage drops that can cause intermittent system issues.

Runs Capacitor – We test capacitor values for accuracy within 10% of rating, inspecting for oil leaks or voltage drops that can cause intermittent system issues.

Blower Wheel – The blower wheel is cleaned and balanced to maintain smooth, quiet operation. Build-up or imbalance can cause vibrations and reduced efficiency.

Blower Wheel – The blower wheel is cleaned and balanced to maintain smooth, quiet operation. Build-up or imbalance can cause vibrations and reduced efficiency.

Carbon Monoxide Test – Using a digital meter, we test for carbon monoxide leaks at the furnace, plenum, and supply registers to ensure your home’s safety.

Carbon Monoxide Test – Using a digital meter, we test for carbon monoxide leaks at the furnace, plenum, and supply registers to ensure your home’s safety.

Burners – We observe the burner flame for color and consistency. A proper blue flame indicates good combustion, while yellow or orange flames can signal dirty burners or airflow issues.

Burners – We observe the burner flame for color and consistency. A proper blue flame indicates good combustion, while yellow or orange flames can signal dirty burners or airflow issues.

Heat Exchanger – The heat exchanger is visually inspected for cracks, rust, or signs of fatigue. Any indication of damage requires immediate attention to prevent dangerous carbon monoxide leaks.

Heat Exchanger – The heat exchanger is visually inspected for cracks, rust, or signs of fatigue. Any indication of damage requires immediate attention to prevent dangerous carbon monoxide leaks.

Gas Lines – All visible gas connections are checked for leaks using a soap-bubble test. We focus on common failure points to ensure your home’s safety.

Gas Lines – All visible gas connections are checked for leaks using a soap-bubble test. We focus on common failure points to ensure your home’s safety.

Temperature Rise – We measure the temperature increase between the return and supply air, ensuring it matches the manufacturer’s specifications for optimal efficiency.

Temperature Rise – We measure the temperature increase between the return and supply air, ensuring it matches the manufacturer’s specifications for optimal efficiency.

Safety Controls – The safety sequence is tested, including door switches and auxiliary safety devices, confirming that each responds properly to system conditions.

Safety Controls – The safety sequence is tested, including door switches and auxiliary safety devices, confirming that each responds properly to system conditions.

Indoor Coil – The indoor coil is checked for cleanliness and potential refrigerant leaks that could affect both heating and cooling efficiency.

Indoor Coil – The indoor coil is checked for cleanliness and potential refrigerant leaks that could affect both heating and cooling efficiency.

Drafting – We ensure the furnace vents properly and check the flue for rust, obstructions, or improper drafting that could allow combustion gases to linger.

Drafting – We ensure the furnace vents properly and check the flue for rust, obstructions, or improper drafting that could allow combustion gases to linger.

Limit Switches & Fan Controls – We test these switches for proper cut-in and cut-out operation to prevent overheating or short cycling.

Limit Switches & Fan Controls – We test these switches for proper cut-in and cut-out operation to prevent overheating or short cycling.

Pilot / Ignition Switch – The ignition system is tested for flame quality and consistent startup. We check for signs of delayed ignition, hard starts, or rollout issues.

Pilot / Ignition Switch – The ignition system is tested for flame quality and consistent startup. We check for signs of delayed ignition, hard starts, or rollout issues.

Duct Work – Ducts are inspected for cleanliness, damage, or separation—especially in attic installations where heat loss is common.

Duct Work – Ducts are inspected for cleanliness, damage, or separation—especially in attic installations where heat loss is common.

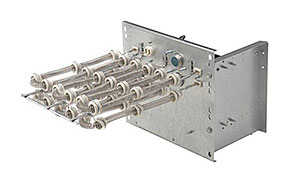

Heat Strips (for Heat Pumps) – We test each strip for proper sequence, amperage, and continuity to ensure efficient supplemental heating.

Heat Strips (for Heat Pumps) – We test each strip for proper sequence, amperage, and continuity to ensure efficient supplemental heating.

Crank Case Heater – We verify amp draw to ensure the heater is functioning correctly, preventing oil foaming and ensuring compressor protection during cold weather.

Crank Case Heater – We verify amp draw to ensure the heater is functioning correctly, preventing oil foaming and ensuring compressor protection during cold weather.

Defrost Controls – We activate and test the defrost cycle to ensure proper function. Technicians will also explain what to expect when the system enters defrost mode.

Defrost Controls – We activate and test the defrost cycle to ensure proper function. Technicians will also explain what to expect when the system enters defrost mode.

Split Temperatures – Lastly, we take split temperature readings to verify overall efficiency. Poor splits often point to restricted airflow or failing components.

Split Temperatures – Lastly, we take split temperature readings to verify overall efficiency. Poor splits often point to restricted airflow or failing components.

Comfort, Reliability and Efficiency

You can count on an Ultra professional to take care of your heating and cooling system with a regular inspection.

Call us today and discover how we can help you: (520) 729-9713.

Disclaimer : For Residential Customers only, During Normal Business Hours Mon-Fri 8:00 AM to 5:00 PM” and “other restrictions may apply”

Free estimates? Absolutely!

He's very pleasant and knowledgeable. He made suggestions and with help from his office prepared a good quote.

Manny was super helpful and thorough in his work. We would trust him to come back anytime for our HVAC needs.

The team covered the floors to keep everything clean, kept me updated on what they were doing, and communicated when there were any unforeseen difficulties/changes (for example, the thermostat needed to be moved).

Very professional efficient and friendly. Cost for regular maintenance is very reasonable and a great value.

Emmanuel was friendly and clear on his explanation of what had gone with our AC He also wore a mask at all time, which was most appreciated